cmm BRIDGE | universal

CMM bridge | universal

The UNIVERSAL family represents the latest generation of CMMs.

Ideal for both traditional point-to-point measurements and more advanced scanning cycles using both contact and laser technology. The exceptional structural rigidity of the UNIVERSAL series makes it particularly suitable for use with 5-axis scanning systems and for measuring gears and gear wheels.

The features are specially designed to reduce the number of parts, simplify construction, and reduce costs and maintenance time.

The COORD3 UNIVERSAL series integrates, for the first time in the market, the automatic temperature compensation system with wireless technology. The fully automatic system dynamically corrects errors induced by environmental temperature changes in the 16-26°C temperature range. In addition, the use of high-resolution optical scales (0.1 µm) untethered from the substrate avoids distortions induced by deformation of the main structure.

CMM universal

- Ultra-rigid mechanical structure for maximum accuracy in scanning

- Highly responsive structure to environmental temperature changes

- CAD FEA-assisted design of the extruded aluminum alloy crossmember to minimize inertial effects at maximum dynamics

- Monolithic granite support surface with integral dovetailed slide rail

- Grid of M8 holes for fixing equipment on the support surface

- Sliding system on pneumostatic pads with ultra-rigid isostatic support on all measuring axes

- Z-axis pneumatic balancing

- High-resolution (0.1-micron) carrier-scrolling optical scales with dynamic signal processing

- Digital trajectory control system for metrological performance optimization

- Hysteresis-free toothed belt drive system on all axes

- Passive environmental vibration isolation system

- Easy access to the measurement volume

- Vector positioning speed up to 866mm/sec

- Vector acceleration up to 1500mm/sec2

- Temperature rating for metrological performance: 20°C

- Temperature range: 18 - 22°C (extended range 16 - 26°C)

- Maximum allowable temperature gradients: 0.5°C/hour - 2°C/24 hours (extended range 5°C/24 hours)

- Operating temperature range: 15 - 35°C

- Relative humidity: 40 - 80% (non-condensing)

- Maximum ambient vibrations: 30 mm/sec2 1-10Hz | 15 mm/sec2 10-20Hz | 50 mm/sec2 20-100Hz

- Minimum pressure: 5 Bar -72PSI

- Compressed air consumption: 100Nl/min

- Power supply: 230v 50Hz or 110v 60Hz;

- Maximum power consumption: 10A 1200W

Each COORD3 CMM is tested according to UNI EN ISO 10360-2 standards.

UNIVERSAL 07.07 - 09.08 - 10.08

The indicated performance is valid under the following conditions:

- PH10M/PH10MQ/PH20/TP20/TP200: Ø4mm x 10mm stylus

- PH10MQ/SP25: SM1, stylus Ø 5mm x 50mm

- REVO: RSP2/RSH175-RSP3-1/SH25-1, 20mm stylus

- L= measurement length in mm

- Ambient temperature conditions:

T1 : 18÷22°C; Max gradients: 1.0 °K/h - 2.0 °K/24h - 1.0°K/m

T2 : 16÷26°C; Gradients max: 1.0 °K/h - 5.0 °K/24h - 1.0°K/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum Permissible Error on point grip according to ISO 10360-2

[3] Maximum Permissible Error of Point Grip on scanning according to ISO 10360-4 for touch probes SP25M/SP80, ball Ø 25 mm - REVO RSP3-1

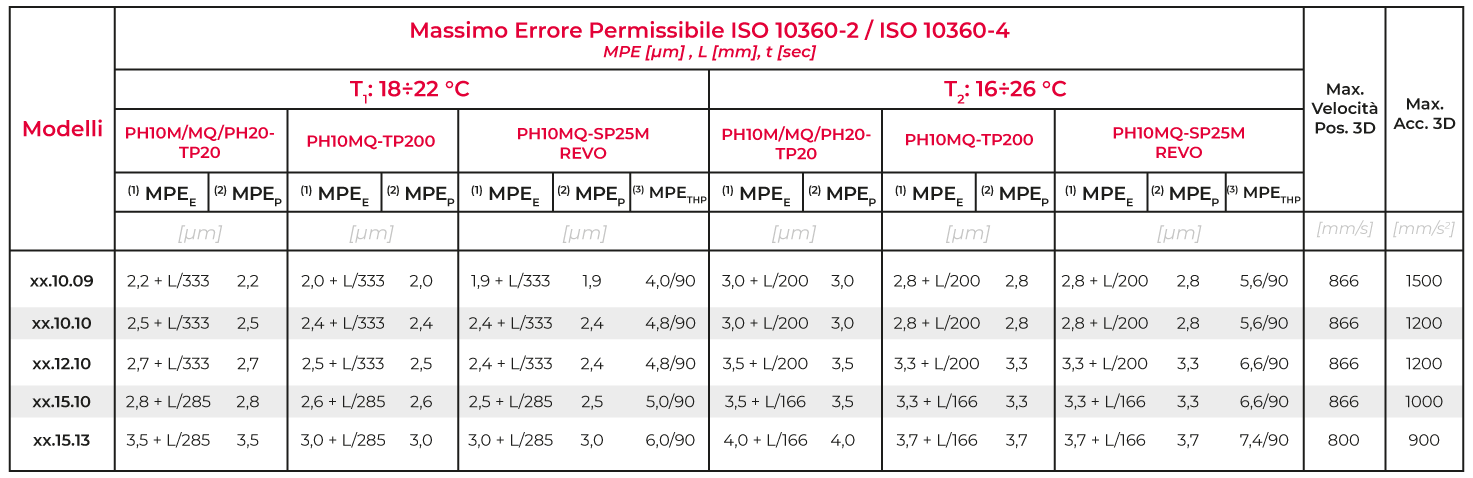

UNIVERSAL 10.09 - 10.10 - 15.10 - 15.13

The indicated performance is valid under the following conditions:

- PH10M/PH10MQ/PH20/TP20/TP200: Ø4mm x 10mm stylus

- PH10MQ/SP25: SM1, stylus Ø 5mm x 50mm

- REVO: RSP2/RSH175-RSP3-1/SH25-1, 20mm stylus

- L= measurement length in mm

- Ambient temperature conditions:

T1 : 18÷22°C; Maximum gradients: 1.0 °K/h - 2.0 °K/24h - 1.0 °K/m

T2: 16÷26°C; Gradients max: 1.0 °K/h - 5.0 °K/24h - 1.0 °K/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum Permissible Error on point grip according to ISO 10360-2

[3] Maximum Permissible Point Grip Error on scanning according to ISO 10360-4 for touch probes SP25/M/SP80/REVO, sample ball Ø 25 mm - REVO RSP3

- Automatic multi-probe temperature compensation

- Active security system with volumetric scanners

- Active anti-vibration system

- Dryer

- Modular piece equipment system

- Modular protection booth

- Models and dimensions

COORD3 UNIVERSAL CMMs are available with the following measuring strokes (Y.Z mm):

7.7/9.8/10.8/10.10/12.10/15.10/15.13

request a visit from one of our agents

Strada Statale 25, No. 3 - 10050 - Bruzolo (TO) - Italy

TELEPHONE

+39 011 963 5511

TECHNICAL ASSISTANCE

service@coord3.com

SALES

info@coord3.com

ADMINISTRATION

finance@coord3.com

PURCHASING

acquisti@coord3.com

© 2023 COORD 3 S.R.L. | Via XX Settembre, 26 - 00187 Roma (RM) - Italy | REA C.C.I.A.A. No. 1667509 Rome - Paid-up share capital: Euro 50,000.00 | P.IVA\C.F: 11287420019 | SDI ZBGTBLC | ISO 9001 Certified | Privacy Policy | Cookie Policy